THE DELIMARA LIGHTHOUSE

Location

A fifteen minute drive away from the Malta International Airport towards Delimara Point, the extreme southern tip of the Maltese archipelago, we find a landmark building that is an important testimony of Malta’s maritime history, the Delimara lighthouse. The road to the lighthouse skirts the picturesque fishing village of Marsaxlokk and many of the beautiful bays and creeks that adorn the southern coast of the island.

The Delimara lighthouse is the only one in Malta to be equipped with Fresnel Lenses. Augustin Fresnel was a French scientist who in 1823 invented a lens system to efficiently reflect most of the light sources out to sea. The Fresnel lens reduces the amount of material required compared to a conventional lens by dividing the lens into a set of concentric annular sections. An ideal Fresnel lens would have infinitely many such sections. In each section, the overall thickness is decreased compared to an equivalent simple lens. This effectively divides the continuous surface of a standard lens into a set of surfaces of the same curvature, with stepped discontinuities between them. In some lenses, the curved surfaces are replaced with flat surfaces, with a different angle in each section. Such a lens can be regarded as an array of prisms arranged in a circular fashion, with steeper prisms on the edges, and a flat or slightly convex centre. In the first (and largest) Fresnel lenses, each section was actually a separate prism. ‘Single-piece’ Fresnel lenses were later produced, being used for automobile headlamps, brake, parking, and turn signal lenses, and so on.

Fresnel produced six sizes of lighthouse lenses, divided into four orders based on their size and focal length. A first-order lens has a focal length of 920mm and an optical area 2590mm (8.5 ft) high. The complete assembly is about 3.7m tall and 1.8m wide. The smallest (sixth-order) has a focal length of 150mm and an optical area 433mm high. The one at the Delimara lighthouse is equipped with a lens very close to that of a third-order and with a focal length of 530mm and a height of 1.6m.

After this invention the French were the leading suppliers of lighthouse lenses until the British Glass factory, Chance Brothers Ltd, adopted a revolutionary design. James Timmins Chance had the idea of fixing the Fresnel lens on a rotating table at the centre of which he placed the light source. The rotation of the lenses around the light source produced light beams that, from out at sea appeared as light flashes instead of the than traditional fixed light. By using transparent and coloured lenses and using different rotation speeds, each lighthouse could now have its own distinctive light pattern known as the ‘Lighthouse Signature’.

In the Delimara lighthouse the table is rotated by a mechanism very similar to that of a clock. This clockwork mechanism is driven by a weight hanging from the very top of the lighthouse and when released it unwinds the drum of the mechanism and turns the gear train. A friction governor in the gear train controls the rate of descent of the weights. In so doing it results in a number of revolutions per minute on its input shaft that drives the rotating table with its lenses around the central light source. Chance Brothers’ clocks were equipped with a minute dial so that the lighthouse keeper could compare the number of turns per minute of the output shaft of the mechanism with a pocket watch. If necessary, he would adjust the governor to produce the required revolutions per minute of the rotating table and consequently of the light flash frequency. each lighthouse mechanism produced by Chance Brothers was unique as it was produced for that specific lighthouse, composed of singularly hand cut glass prisms.

The light source at the Delimara lighthouse was provided by a pear-shaped paraffin tank made of copper.

Half rounded rods, crafted artistically on each end in the shape of a lion’s paw, reinforce the tank. This style is typically Victorian and was in vogue at the time the Delimara Lighthouse was built. Indeed this Victorian Cabriole style was mostly used in furniture. This could indicate that this tank is the original one used when the lighthouse was constructed in the 1850s. Here we should mention that in between 1850 and 1896 the system used was different. The tank has a hand pump to pressurise the fuel supplying the three co-centric wicks that were located just above the tank. An identical tank which still has all its original features, complete with the three co-centric wicks, can be found at the Maritime Museum, Vittoriosa. Presumably, this is a spare unit from the Delimara Lighthouse.

In a document dated 1948 written by Chance Brothers and Co Ltd., there are instructions for use of the clock mechanism.The document states that ‘the machine is driven by a steel wire rope, which passes over a barrel to which it is secured by means of a thimble. When the weights are being wound up a self maintaining power motion comes into action, thus preventing the winding from interfering with the continuous running of the clock. The weights should be just sufficient to drive the apparatus at its proper speed; less weight than at first may be required after the machine has been at work for some time. The speed of the clockwork is regulated by means of a centrifugal governor which is controlled by a central spring (labelled as D) which is adjusted by the nuts (labelled as e) on the shaft itself. …. The shafts in the clock itself are run on ball bearings. …..’

The St Elmo and the Gordan lighthouses used a completely different system to the one at Delimara. A schematic diagram found in the keeper’s room at Tal-Gordan shows that it consisted of 21 reflectors mounted on a triangular rotating base (with seven reflectors on each side) with each reflector having its own oil lamp complete with tank. Documents reveal that the keeper of St Elmo used to share spares with Tal-Gordan lighthouse thus indicating that these had similar, if not identical, light systems. A section plan of the Gordan Lighthouse dated 1907 found in the Works Division archives confirms that the St Elmo lighthouse used a number of reflectors to produce the light beams.

History of the Lighthouse

The Delimara Lighthouse was commissioned by Governor O’Ferrall in 1850 but was initiated at around 1854. In fact a plan of the site to be acquired for the construction of this lighthouse is dated 1854. It was functional by 1855.

The Delimara lighthouse consists of a rectangular block of two stories and a central octagonal tower. There are three doors at ground level. The door on the left side leads to a four-sided room which in turn leads to a flight of stairs on the left, and another much smaller room on the right hand side. The door on the right leads to a four-sided room which in turn leads to another smaller room which was used for storage of fuel. On the right hand side of the ground floor is a small extension which was constructed in two phases, the first one measuring only 1.2 metres and carried out in 1864 while the second enlargement brought the room to the present size. This addition is accessed through a doorway to the front room.

The upper floor is practically identical to the lower floor except for the absence of the additional small room on the right of the lower floor.

The central door opens into a corridor which is situated in front of the entrance to the tower, and in turn the corridor leads to the two front rooms on each side. The base of the tower is slightly set back to give room to the corridor. At one point a room was added on the roof of the lighthouse, its roof having been constructed with steel beams and stone slabs. In 1984 it was decided to replace the badly corroded ladder and railing on the outside of the lantern housing.

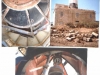

Globigerina limestone was used for the construction of the lighthouse but the upper courses of the coping which secure the lantern housing on the summit of the building were made of hard stone. This lighthouse sustained damages during World War II and indications of shrapnel are still easily identified on the outside elevations. Indeed damages involved breakages to a number of glass panes.

The Light Source

When the Delimara Lighthouse was completed and operational in 1855, the lighthouse had a static red lantern. In 1896 this light source was replaced by a more powerful gasoline lamp which was operated by a hand wound mechanism which produced beams of alternating red and white light flashed at intervals of 30 seconds. Its arc of visibility ranged from 19 degrees to 295 degrees with a radius spreading up to 15 miles. In 1956 it was reported that the mechanism was defective and that it had a tendency to stall. The timing was also irregular and could not be adjusted. In that year it was decided to replace the revolving red and white light with a fixed white light which would only be visible in certain sectors and at certain distances. There were also missing lenses which were causing an unbalanced lantern.

Mariners could not easily locate the position of the lighthouse during daytime. In 1950 it was decided to paint the outside of the tower in black and white stripes for mariners to recognise it immediately. The lighthouse was decommissioned around 1989-90. A Hydrographic drawing dated 1984 indicated that the lighthouse produced two flashes of light every 12 seconds at 35m in height and visible at a distance of 18 miles. When the lighthouse was decommissioned an automated light source was placed on a two storey building close-by emitting two white flashes every 12 seconds with a range 18 nautical miles.

Din l-Art Ħelwa Restores the Lighthouse

By summer 2005, the Lighthouse had not been in use for several years and was facing abandon. Din l-Art Ħelwa approached the then Malta Maritime Authority, now Transport Malta, and offered to manage and restore it. This request was met with approval and the lighthouse was officially devolved to the organisation soon after. On 16 February 2006, Din l-Art Ħelwa’s Executive President Martin Scicluna and Secretary General Edward Xuereb, signed a historic agreement with Mr Marc Bonello, Chairman of the MMA, allowing our organisation the privilege of involvement with one of the only two existing lighthouses in Malta. Council members involved at different stages in the restoration included Arch. David Mallia, Ian Camilleri, Maria Grazia Cassar, Josie Ellul Mercer and Stanley Farrugia Randon. The remote location of the lighthouse and the badly maintained roads made this more difficult for everyone.

Communications and Competitiveness Minister Ċensu Galea, on behalf of the Malta Maritime Authority, presented Din l-Art Ħelwa with initial funds to assist with the restoration. Din l-Art Ħelwa knew this was going to be complex but work started soon after and was planned in three phases. The lighthouse had always accommodated a lighthouse keeper and his family and was conveniently already divided into two living spaces. The final aim was that of converting these so as to offer exciting visitor accommodation in a historic and unusual site.

The first phase of restoration involved the restoration of the exterior and included repairing damage to the walls, roof and tower. All cement accretions added in previous years were removed and the mortar joints were plastered with a hydraulic lime-based mix. The external apertures required extensive maintenance and any missing timber apertures were replaced. The second phase involved internal works such as cleaning the stencilled concrete floor, plumbing and electricity, maintenance of internal apertures and the installation of kitchens and bathrooms. The first two phases were completed in the first months of 2008. The third and last phase, perhaps the most delicate, included the restoration of the light and lantern mechanisms and their housing, including the complex system of glass prisms. This crucial part of the project had to be delayed due to financial constraints until it was made possible by a generous sponsorship from GasanMamo Insurance Ltd, a leading insurance company that coincidentally uses a lighthouse as its logo. The process encountered further delays as restoration of the copper canopy and iron work proved complex and required much research and studies before it could take place.

Much of the work could not be done on site as the housing had to be dismantled piece by piece, and every single nut and bolt treated lovingly by hand. The canopy hood of a lighthouse mechanism is in itself a complex piece of engineering. Its restoration is even more so. Not many blacksmiths were prepared to take on such a commitment especially working in such an exposed site as the Delimara promontory and its cliff edge. However, we were fortunate that Anthony Spiteri of JMS Art Metal Craft Ltd accepted to undertake this daunting challenge.

The glass panes had to be removed one by one with much difficulty as many were broken and others were replaced by wooden planks. It was then necessary to free the canopy structure from its base of coralline limestone. It was attached to this by an iron ring and hold-down bolts on the inside.

Unfortunately many of the coralline limestone stones were cracked by the corroded bolts, and the ring was also in a bad state of preservation. These had to be replaced. The housing was then hauled done by crane in a spectacular manoeuvre after which the mechanism with its precious lenses was lowered down. When the aged white paint on the cast iron housing and copper parts was removed, this brought to light other problems in the structure which were not evident before. The housing was found to be made of cast iron which is brittle by its very nature. It was broken in different parts at its base and this was probably intentionally done when the housing was originally fixed to the stone base. We found that the existing pre-drilled holes did not match the bolts which had been prepared for it in the stone. Joints and corroded holes were filled and in some areas a blacksmith was asked to replace numerous corrosive and missing parts. The cast iron was painstakingly cleaned, and then given a protective layer to prevent corrosion.

Extensively corroded parts had to be replaced. Glass panes protect the lens mechanism all around but this is shielded above by copper sheets which form a protective canopy. Rain water is drained away through gutters which are also made of copper. Both the cast iron and the copper components had corroded extensively, possibly affecting each other due to galvanic corrosion. Copper hooks were manufactured and placed on the interior of the landward side of the housing. It is thought that these served to hang an apparatus which prevented the light from the lantern shining towards the landward side. The whole mechanism and housing were finally returned to their place in February 2014.

Yet another challenge was to delay completion. When the kitchens and bathrooms were fitted it was found that the lighthouse had no drainage system at all, and not even a cesspit leaving us to imagine where and how effluence of hygiene services went, somehow reaching the sea! As there are no drainage systems in this area of Delimara, the Din l-Art Ħelwa restoration team decided that a cesspit had to be constructed. This took place but not without long deliberations on its location and size which all had to undergo regulatory applications and approvals. Nevertheless, we remained totally committed to the project, and finally this problem too was overcome. Thus, Malta’s Delimara Lighthouse is now finally ready to be lived in. with its splendid location facing the southern straits towards North Africa and close to so many popular bathing areas, we hope it will be enjoyed by many generations to come.

Our last challenge would be to restore the clockwork mechanism which was originally used to turn round the red glass panes.

Comments are closed.